In this step-by-step guide, we will outline the process of troubleshooting a gas range stove. The purpose of this guide is to provide a clear and concise set of instructions to help users identify and resolve common issues with their gas range stoves. By following the outlined steps, users will be able to troubleshoot and potentially fix problems such as burner ignition issues, uneven heating, and gas leaks, ensuring the safe and efficient operation of their gas range stoves.

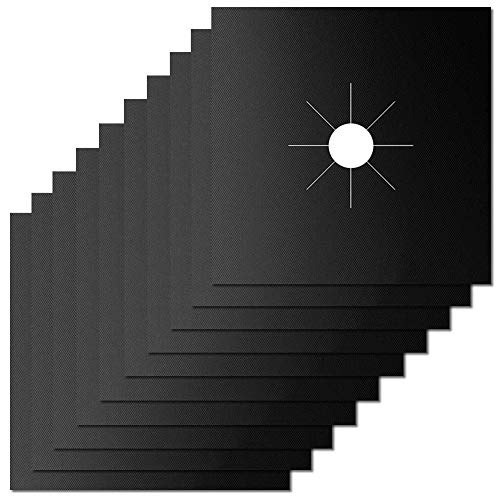

Top Selling Gas Range Stoves

Identifying the 5 Key Causes for Gas Oven Heating Issues: Comprehensive Gas Range Troubleshooting Guide

Checking the Gas Supply

To ensure the gas supply is functioning correctly, follow these steps:

- Check the gas supply valve: Locate the main gas supply valve and ensure it is in the open position. Turn the valve counterclockwise to open it fully. If it is already open, proceed to the next step.

- Inspect for leaks: Use a gas leak detector or a mixture of soapy water to check for any gas leaks. Apply the solution to the gas connections, including the main supply valve and any connections leading to the gas appliance. Look for bubbles forming, indicating a leak. If a leak is detected, close the gas supply valve immediately and contact a professional technician to address the issue.

- Verify other gas appliances: Confirm that other gas appliances in your home, such as stoves or water heaters, are functioning properly. Turn each appliance on and ensure it ignites and operates as expected. If any appliance fails to work or exhibits unusual behavior, it may indicate a problem with the gas supply. In such cases, contact a qualified technician for further assistance.

By following these steps, you can ensure that your gas supply is open and free of leaks, and verify the proper functioning of other gas appliances in your home.

Inspecting the Igniter

To check if the igniter is glowing when the stove is turned on, follow these simple steps:

- Ensure safety: Before inspecting the igniter, make sure the stove is turned off and unplugged to avoid any potential accidents or injuries.

- Access the igniter: Locate the igniter component, which is usually positioned near the burner. This may require removing the burner cover or opening the access panel, depending on the stove model.

- Turn on the stove: Plug the stove back in and turn it on. Select the desired burner and set it to the ignition position.

- Observe the igniter: Watch the igniter closely for any signs of glowing. If the igniter emits a bright, steady glow, it indicates that it is functioning properly. On the other hand, if the igniter does not produce any glow, it may need to be replaced.

Example 1: When the stove is turned on, the igniter should emit a bright, orange glow, similar to a hot coal. If the igniter does not light up at all, it suggests that it is not receiving the necessary electrical current to ignite the gas.

Example 2: A malfunctioning igniter can sometimes emit a faint glow or a flickering light. In such cases, the igniter may be partially defective, leading to unreliable ignition and potential issues with the stove’s performance.

Remember, if the igniter is not glowing when the stove is turned on, it is recommended to reach out to a qualified technician or refer to the manufacturer’s instructions for further troubleshooting or replacement instructions.

Examining the Burner

To inspect the burner for any clogs or debris, start by ensuring the burner is turned off and has completely cooled down. Carefully remove any protective coverings or grates surrounding the burner. Take a moment to visually examine the burner for any visible debris, such as food particles, grease, or other obstructions.

If you spot any clogs or debris, it is crucial to clean or unclog them to maintain optimal burner performance. Before starting the cleaning process, make sure the burner is disconnected from any power source to prevent accidents. Depending on the type of burner you have, you may need a small brush, a soft cloth, or a can of compressed air to clean it effectively.

Gently brush away any loose debris on the burner’s surface, ensuring not to damage any delicate parts. For stubborn clogs or buildup, dampen a soft cloth with warm, soapy water and carefully wipe the affected areas. Avoid using abrasive cleaners or harsh chemicals, as they can damage the burner’s components.

If the clog persists, you can use a can of compressed air to blow away any remaining debris. Hold the can upright and direct short bursts of air into the clogged areas. Be cautious not to damage any sensitive parts of the burner while doing so.

Once you have finished cleaning or unclogging the burner, allow it to dry completely before reassembling any protective coverings or grates. Double-check that everything is securely in place before turning the burner back on and resuming its use.

Regularly inspecting and cleaning the burner will help ensure its longevity and efficiency.

Checking the Gas Valve

To ensure the gas valve is functioning correctly, follow these steps:

- Inspect for any visible damage: Start by visually examining the gas valve for any signs of physical damage, such as cracks, leaks, or corrosion. If you detect any damage, it is crucial to contact a professional immediately to address the issue.

- Check for proper gas flow: Turn off any gas appliances connected to the valve and ensure the gas supply is on. Then, slowly open the gas valve all the way. You should hear the sound of gas flowing through the valve. If there is no gas flow or you notice a weak flow, it might indicate a problem with the valve. In this case, it is recommended to consult a professional to further evaluate the situation.

- Test for continuity: If you suspect there may be an issue with the electrical components of the gas valve, you can perform a continuity test using a multimeter. Start by disconnecting the power to the valve. Set your multimeter to the continuity or resistance mode, and touch the probes to the terminals on the gas valve. If there is no continuity or an abnormally high resistance reading, it could indicate a faulty electrical connection or a malfunctioning valve.

- Consult a professional: If you are unsure about any aspect of checking the gas valve or if you encounter any irregularities during the process, it is always best to consult a professional. Gas-related issues can be dangerous and should be handled by trained technicians to ensure safety and proper repairs.

Remember, the safety of your gas system is paramount, so do not hesitate to seek professional assistance if you have any concerns about the functionality of your gas valve.

Verifying the Safety Valve

To ensure the safety valve is not stuck, follow these steps:

- Inspect the safety valve: Check for any visual signs of damage or debris around the valve. Look for any signs of leakage or corrosion. Make sure there are no obstructions that may interfere with the valve’s operation.

- Perform a manual test: Gently push down on the valve to check if it moves freely. It should be able to open and close without any resistance. If it feels stuck or does not move easily, it may need to be replaced.

- Verify the valve’s functionality: If the safety valve appears to be stuck or is not operating correctly, it is crucial to have it tested by a qualified professional. They will be able to perform a thorough examination and determine if replacement is necessary.

Remember, a properly functioning safety valve is crucial for maintaining the safety of the equipment or system it is installed on. If in doubt, always consult with a professional technician to ensure the safety valve is in good working condition.

Testing the Control Board

To properly test the control board, start by visually inspecting it for any signs of visible damage, such as burnt components, cracked circuits, or loose connections. Pay close attention to any wires or connectors that may appear disconnected or frayed. If any damage or loose connections are found, it is crucial to address them before proceeding further.

After the visual inspection, it is time to test the functionality of the control board. Connect the necessary power source to the board and ensure it is properly grounded. Activate the relevant controls and observe the board’s response. Check if the board powers on, displays any error codes or indicators, and executes the desired functions. If the control board fails to operate as expected or shows any irregular behavior, it may indicate a faulty component or malfunction that requires professional assistance.

If you are unsure about any aspect of testing the control board or lack the necessary technical expertise, we strongly recommend seeking professional assistance. A knowledgeable technician will have the expertise and equipment to diagnose and repair any issues with the control board accurately.

Remember, proper testing of the control board is essential to ensure the reliable and safe operation of your equipment.

Key Takeaways

In conclusion, we have provided a comprehensive troubleshooting guide for gas range stoves. We discussed common issues such as burner ignition problems, uneven heating, and gas smells. We outlined step-by-step solutions, including checking the gas supply, cleaning the burners, and inspecting the ignition system. Additionally, we emphasized the importance of safety precautions and the need to consult a professional if necessary. By following these troubleshooting tips, users can effectively address and resolve common problems with their gas range stoves, ensuring optimal performance and safety in the kitchen.

Necessary Equipment

Troubleshooting Techniques

One suggestion I have is to include some troubleshooting tips for specific stove models.

I had a similar issue and this article helped me troubleshoot and fix it.

This article saved me from calling a technician and spending unnecessary money. Thank you!

I would love to see more articles like this for other appliances. Keep up the good work!

Great article! I found the step-by-step instructions very helpful.

I appreciate the clear explanations and the tips for common problems.